Mercedes EQ battery protection systems utilize advanced materials and engineering to ensure robust safety measures. Sturdy casings made from high-strength composites and metals absorb impact energy, preventing cell damage. Sophisticated sensors detect hazards, enabling prompt repair processes for optimal vehicle safety and performance. Rigorous testing protocols simulate real-world scenarios, guaranteeing the Mercedes EQ battery protection system's reliability in accidents.

Mercedes EQ battery systems are designed with cutting-edge protection mechanisms, ensuring their resilience against physical impact. This article delves into the intricate strategies employed by Mercedes to safeguard these batteries. We explore the brand’s understanding of EQ battery protection, examining advanced materials and innovative design choices that enhance impact resistance. Additionally, we uncover rigorous testing protocols that mirror real-world scenarios, solidifying the safety of these revolutionary energy storage systems.

- Understanding Mercedes EQ Battery Protection

- Advanced Materials and Design for Impact Resistance

- Testing Protocols Ensure Real-World Safety

Understanding Mercedes EQ Battery Protection

Mercedes EQ battery systems are designed with robust protection mechanisms to safeguard against potential physical impacts and accidents, a critical aspect in the automotive industry. The brand understands that electric vehicles (EVs) face unique challenges regarding their battery health, especially in terms of structural integrity and damage prevention.

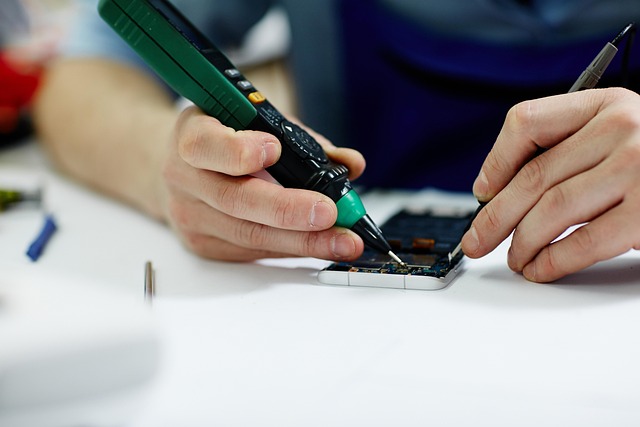

The Mercedes EQ protection system involves advanced engineering and materials science. The batteries are housed within a sturdy casing, often constructed using high-strength composites and metals, which act as a shield against external forces. This protective enclosure is designed to absorb and dissipate energy from impacts, preventing direct damage to the sensitive battery cells. Moreover, Mercedes employs sophisticated sensor technology to detect and respond to potential hazards, enabling rapid dent removal or repair processes via specialized auto repair shops, thus ensuring the vehicle’s overall safety and performance.

Advanced Materials and Design for Impact Resistance

Mercedes EQ battery systems are engineered with advanced materials and a sophisticated design to ensure exceptional impact resistance. These batteries are built to withstand the rigors of modern driving, where unexpected incidents like car collisions or road debris can occur. Specialized protective casing, often incorporating high-strength polymers and metals, serves as the first line of defense against physical damage.

Furthermore, the internal structure of these batteries is meticulously crafted to absorb and distribute energy during impact events. This design includes advanced cushioning mechanisms and reinforced frames that mimic the principles behind car bodywork services, ensuring that even in the event of a collision, the battery retains its structural integrity. Similar to how auto glass repair addresses cracks and chips, these systems are designed to prevent catastrophic failures, enhancing safety and peace of mind for Mercedes EQ owners.

Testing Protocols Ensure Real-World Safety

In ensuring the safety and reliability of their electric vehicles, Mercedes EQ employs rigorous testing protocols designed to mimic real-world scenarios. These tests go beyond standard industry standards, specifically focusing on how the vehicle’s battery systems withstand physical impacts, much like what a car might experience in an accident or during routine collision repair services, such as bumper repair or car dent removal.

The Mercedes EQ battery protection system is engineered to absorb and distribute energy, preventing damage that could compromise performance or safety. Through simulated crash tests, the vehicles’ battery compartments are put through their paces, subjecting them to forces similar to those encountered in auto body repairs. This proactive approach guarantees that when faced with incidents like fender benders or more severe collisions, the EQ batteries remain secure and functional, offering drivers peace of mind.

Mercedes EQ battery systems are designed with a multi-layered approach to withstand physical impact, combining advanced materials, innovative design, and rigorous testing. By integrating these safety measures, Mercedes ensures that their electric vehicle batteries not only meet but exceed industry standards, providing peace of mind for drivers and contributing to the reliability and longevity of EQ models in real-world conditions. This commitment to Mercedes EQ battery protection underscores the brand’s dedication to delivering cutting-edge technology with unparalleled safety.